Product Introduction

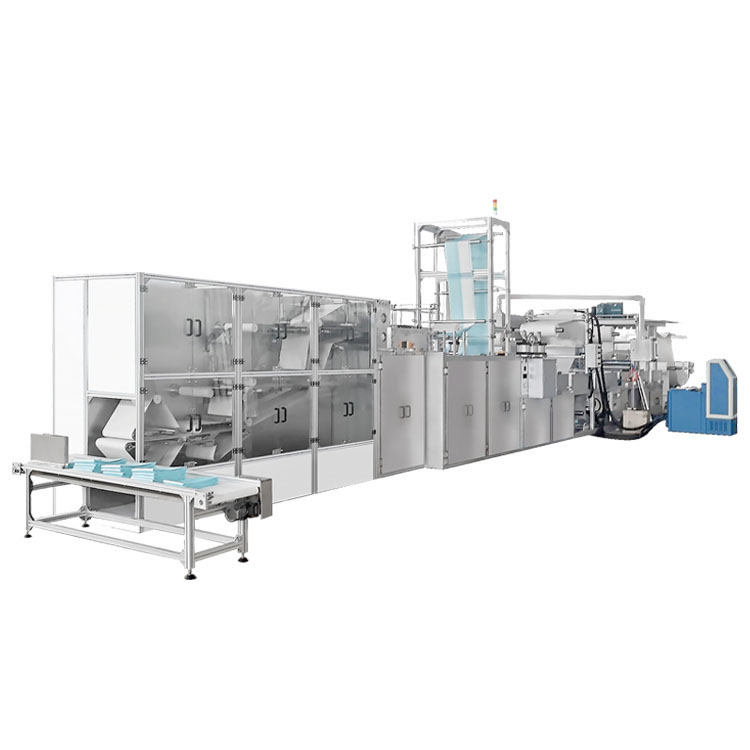

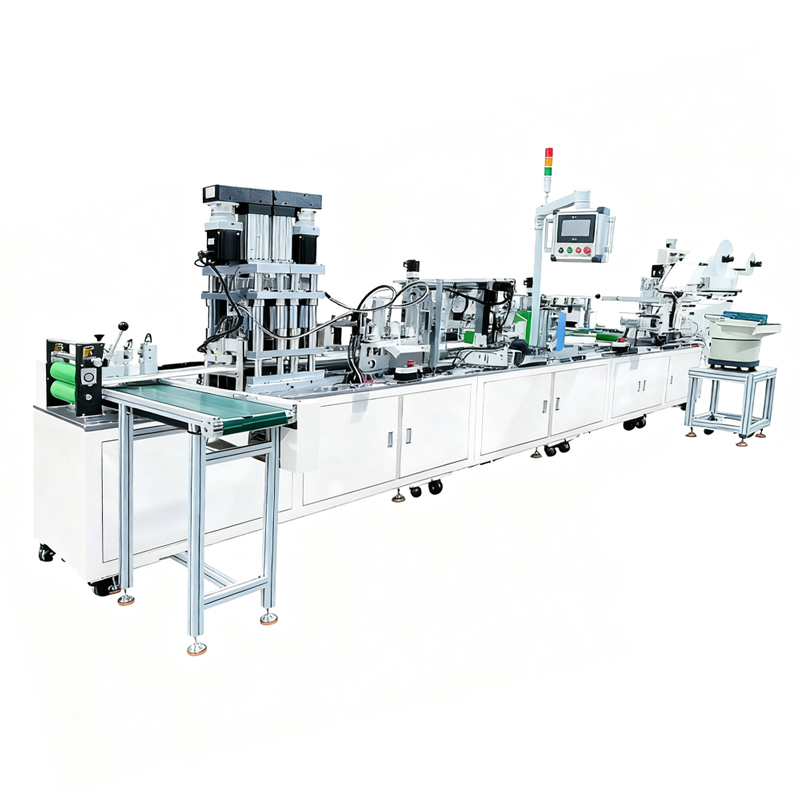

1. Easy operation, gentle start-up, and accurate color registration.

2. A meter counter allows you to set the print quantity according to your requirements, automatically stopping the machine when the number is reached or when the material is cut off.

3. Anilox roller ink transfer ensures uniform ink color.

4. Reliable drying system with automatic circuit breaker upon shutdown.

5. 360-degree continuously adjustable longitudinal registration device.

6. Frequency conversion speed regulation to adapt to different printing speeds.