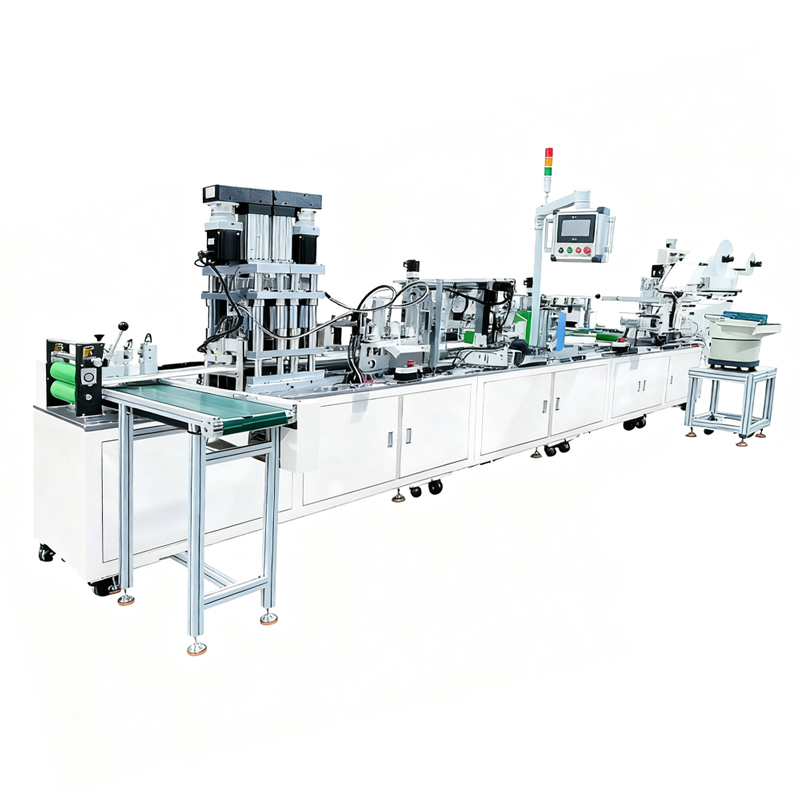

Product Introduction

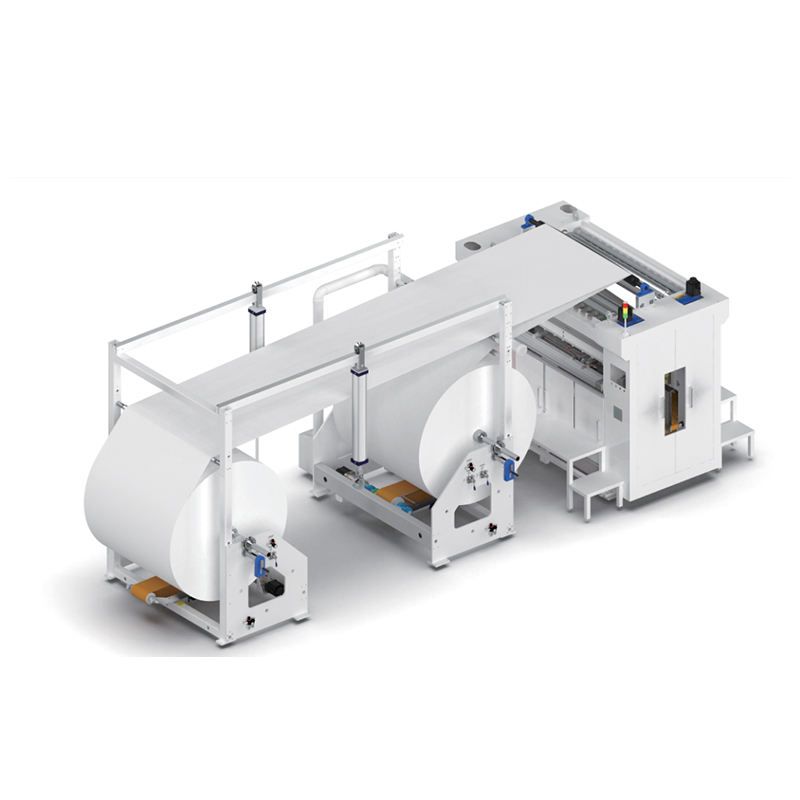

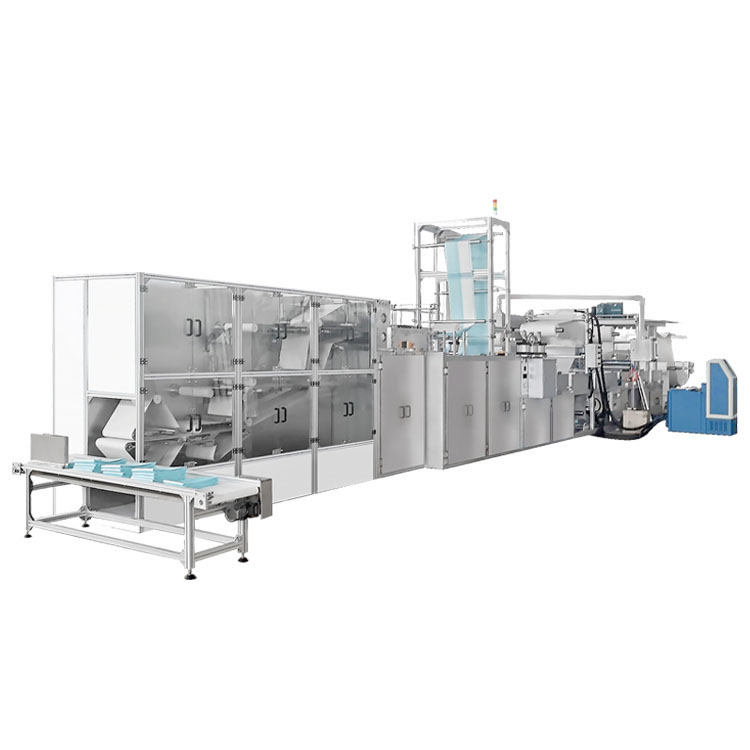

1. It integrates unwinding, edge pressing, embossing (optional), folding, and paper sorting (optional) into a single unit, making operation simple and easy to master.

2. It utilizes servo-tracking unwinding to effectively control tension, resulting in superior folding results and more accurate dimensions.

3. It utilizes voltage stabilization technology and a frequency converter equipped with a blower to automatically adjust air volume based on folding speed, saving 30% energy.

4. It utilizes a fixed stop position, eliminating the need for blower operation during shutdown to prevent paper dropout, significantly reducing energy consumption and paper waste.

5. It utilizes a new rear paper holder, eliminating the need for a shaft and using pneumatic paper loading, significantly reducing labor and paper changing time.

6. It utilizes a novel suction design to effectively improve suction performance and increase folding speed for materials with poor suction properties.