Product Introduction

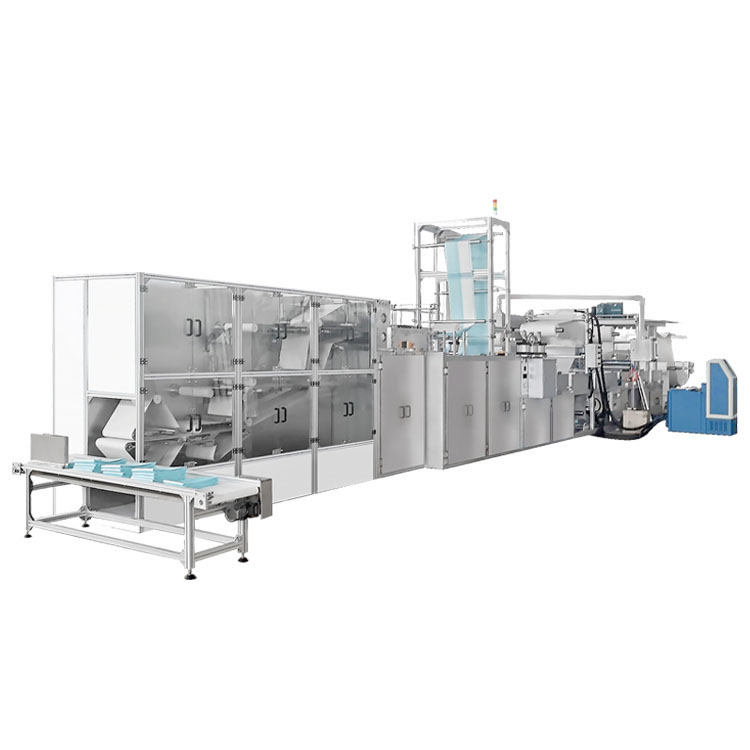

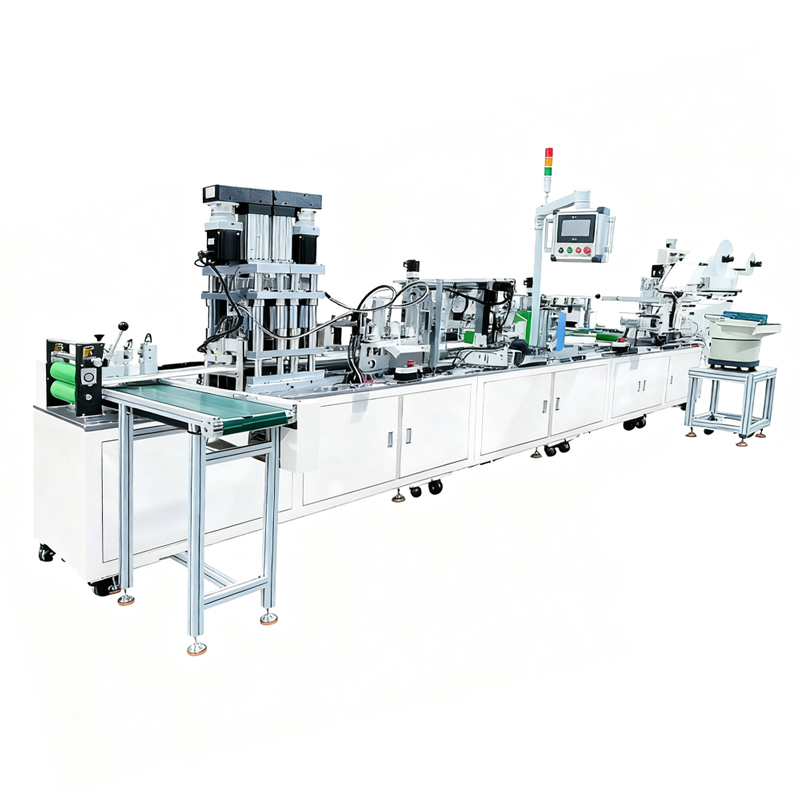

1. The pneumatic shaft allows for quick and easy film application, saving time. The fixed wheel and pneumatic valve can be manually adjusted.

2. The film roll unwinding mechanism uses a motor to automatically move two linear rails in and out.

3. The cursor automatically tracks and corrects film deviation to correct for left or right film deviation.

4. The film-pulling rubber roller is positioned, and the cylinder is manually opened for film change.

5. The spiral cutter technology is suitable for soft-drawing a variety of packaging materials. The film suction belt can be manually adjusted according to product size.

6. Adjusting product size and removing materials is simple and fast.

7. The automatically adjustable height lifting platform is simple and fast. Large and small sizes can be produced on the same machine.

8. The number of products discharged per package is recorded photoelectrically.

9. The discharge port button manually adjusts film deviation to the left or right.

10. The hanging design makes changing product sizes easy and convenient for cleaning and maintenance.

11. IoT-enabled remote data monitoring, storage, and remote program updates.