Product Introduction

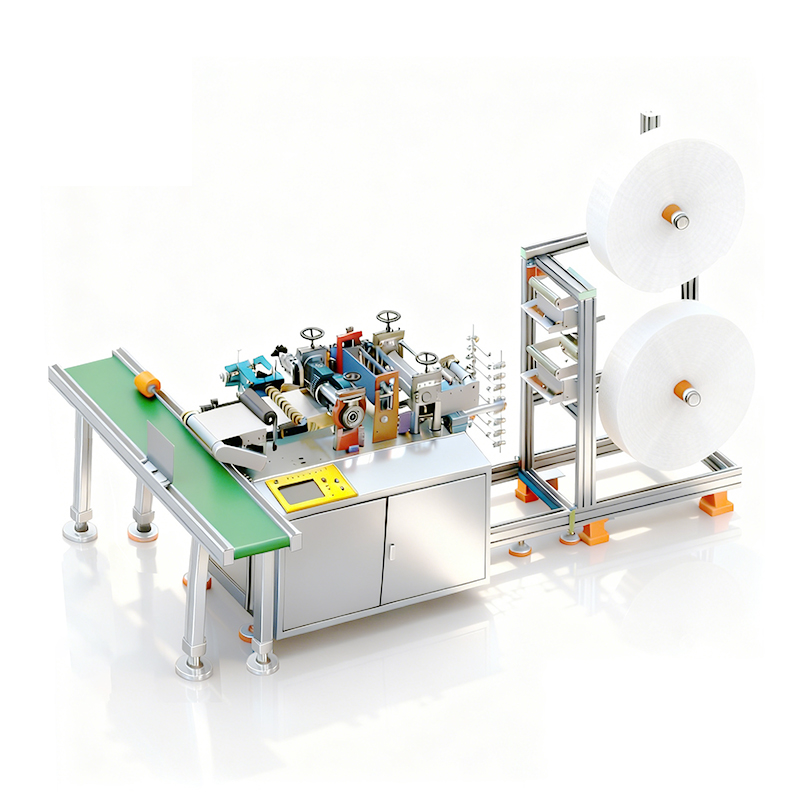

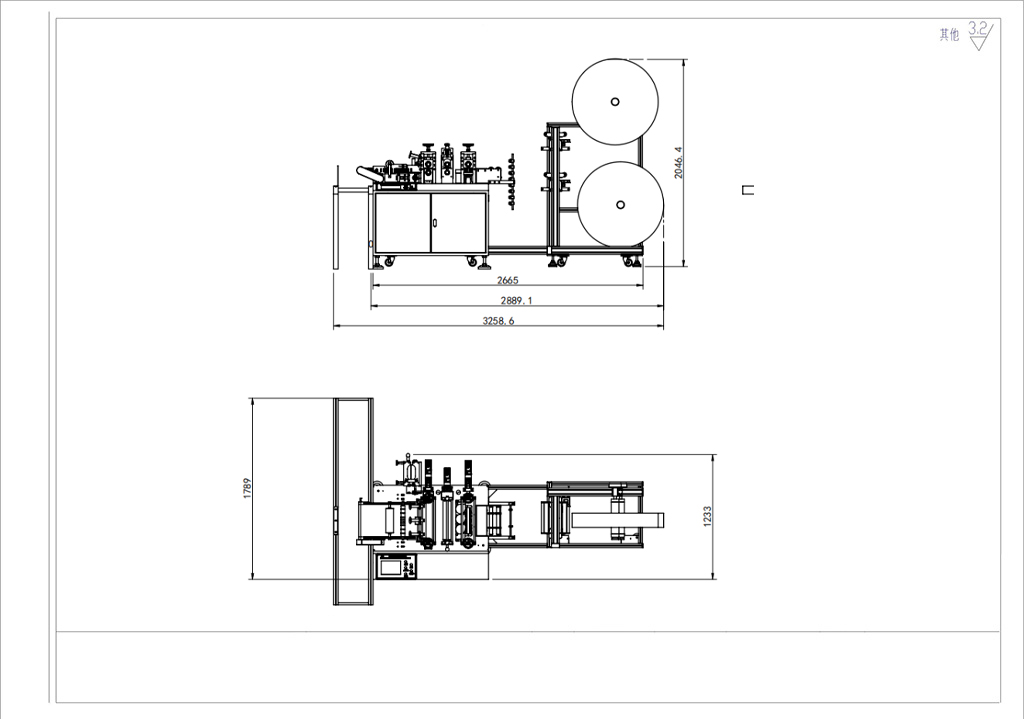

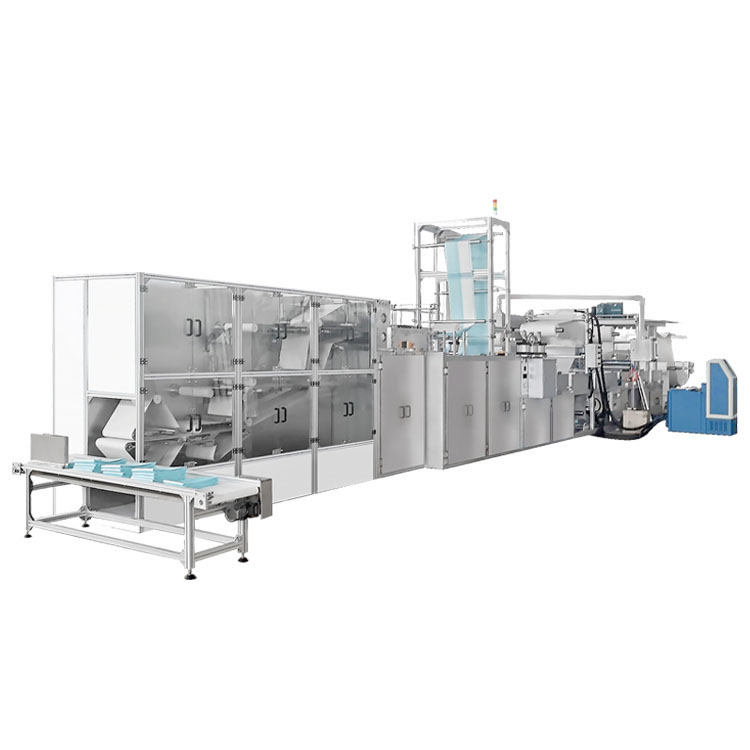

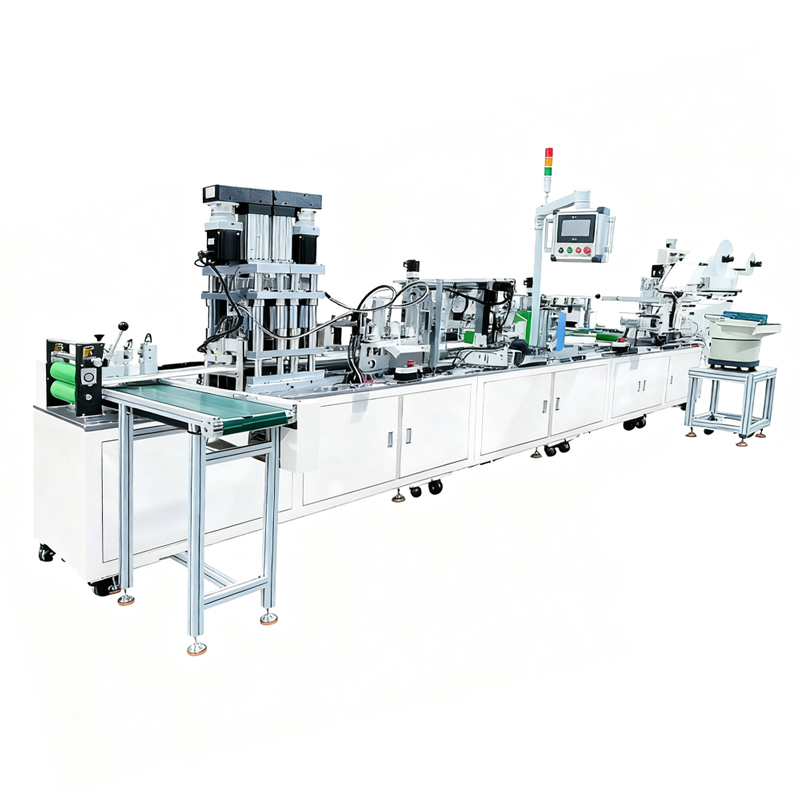

The disposable glove machine consists of: 1. a material rack, a fabric feed roller assembly; 2. a servo welding assembly; a material pulling assembly; a roll cutting assembly; a waste collection assembly; a material pulling assembly; 3. a round hole cutter assembly; a material pulling assembly; 4. a finished product discharge conveyor assembly; a finished product discharge counting and stacking conveyor assembly; and an electrical control system. It automatically completes the processes of feeding, welding, forming, roll cutting, waste collection, discharge counting, stacking, and transporting the spunlace nonwoven fabric for disposable gloves.

The material roll is conveyed in the correct direction by the fabric feed roller assembly and the material pulling assembly, ensuring the spunlace nonwoven fabric is properly oriented. The woven fabric passes through the servo welding group, and the spunlace non-woven fabric passes through the welding wheel. The welding wheel welds the three layers of spunlace non-woven fabric according to the welding points, so that the spunlace non-woven fabrics overlap and are fixed. The upper and lower three layers of spunlace non-woven fabrics will overlap in the pulling group. The pulling group drives the spunlace non-woven fabric into the rolling cutting group. The rolling cutting die rolls the spunlace non-woven fabric into shape to complete the cutting of disposable gloves; the waste is collected by the waste pulling group, and the cut and formed disposable gloves are transported through the discharging conveyor belt. A specified number can be collected on the finished product conveyor belt. After the collection and stacking quantity reaches the specified number, the conveyor belt starts to transport the product out of the stacking place.