Features of the HT150-4-960 Automatic Cartoning Machine

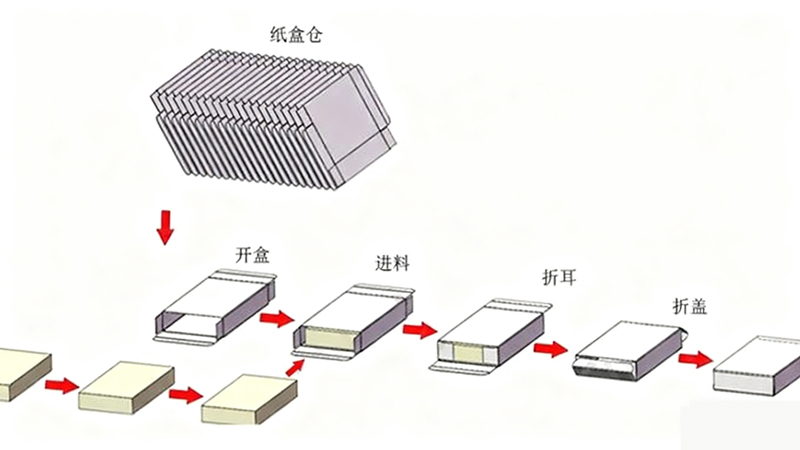

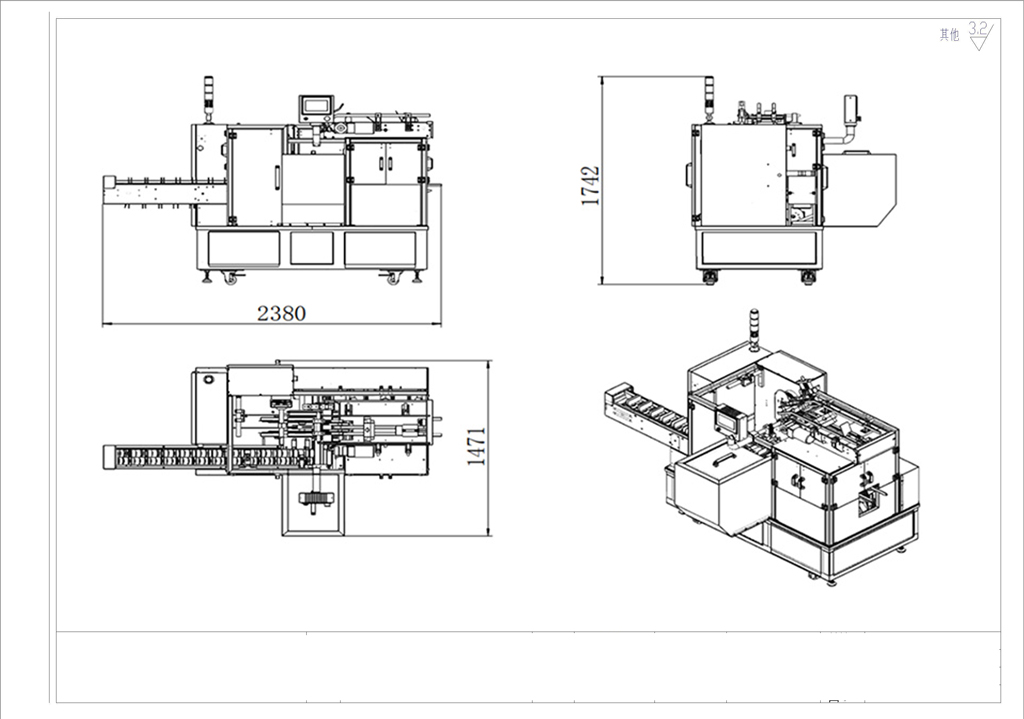

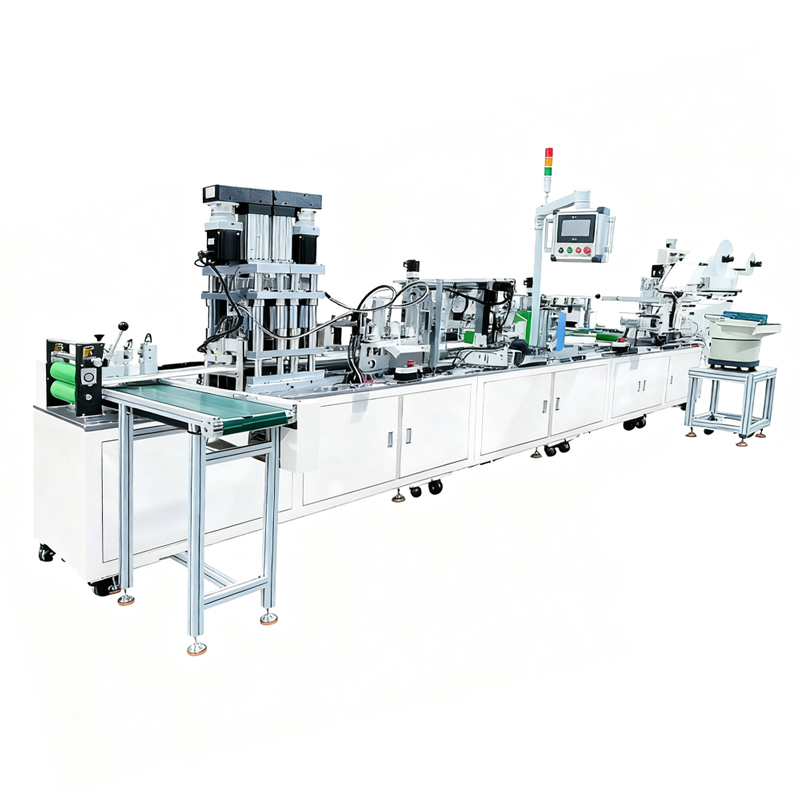

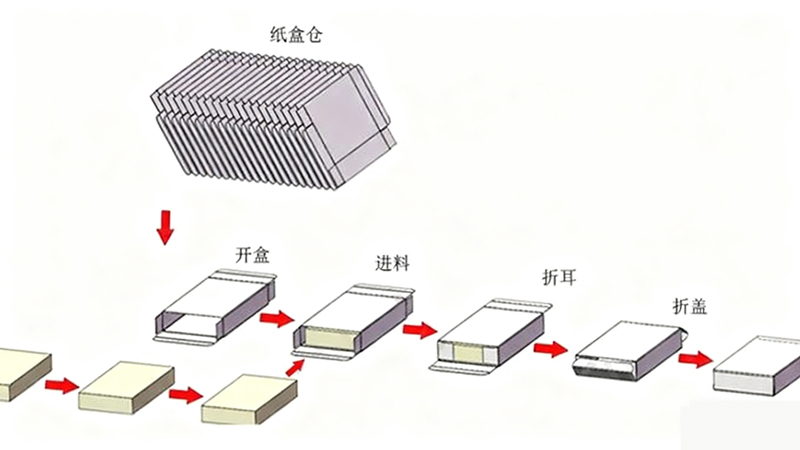

1. This machine, one of our independently developed mass-produced models, integrates carton opening, packing, folding, and sealing, boasting a compact and rational design, simple operation, and easy maintenance.

2. It features front and rear loading, automatic feeding, automatic tray removal, instruction manuals, serial number printing, and reject rejection.

3. A dial scale allows for quick adjustment within the specified range of the same machine, enabling multiple specifications.

4. Product-contact parts are constructed of SUS304 stainless steel.

5. Highly automated: Utilizing a PLC programmable control system, the human-machine interface displays parameters such as cartoning speed, quantity, automatic carton shortage alarm, no product opening, and fault cause.

6. Transmission and friction components are manufactured to strict standards, minimizing wear and reducing component replacement.

7. Optional hot melt adhesive dispensers, hot melt adhesive spray sealers, and mechanical adhesive sealers are available upon request.

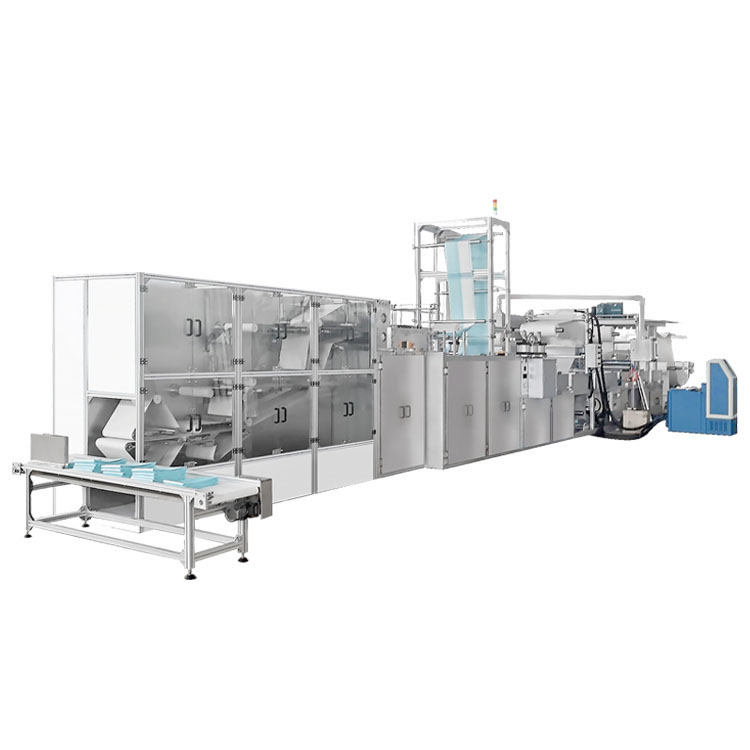

8. This machine can be used independently or connected to other equipment, such as a material handler, robotic arm, 3D packaging machine, pillow packaging machine, stand-up pouch packaging machine, assembly machine, automatic filling machine, labeling machine, inkjet printer, and other mechanical equipment for coordinated operation.

Applications

It is primarily suitable for automated cartoning of small items such as food, medical supplies, toys, stationery, auto parts, cosmetics, hardware, and daily necessities.