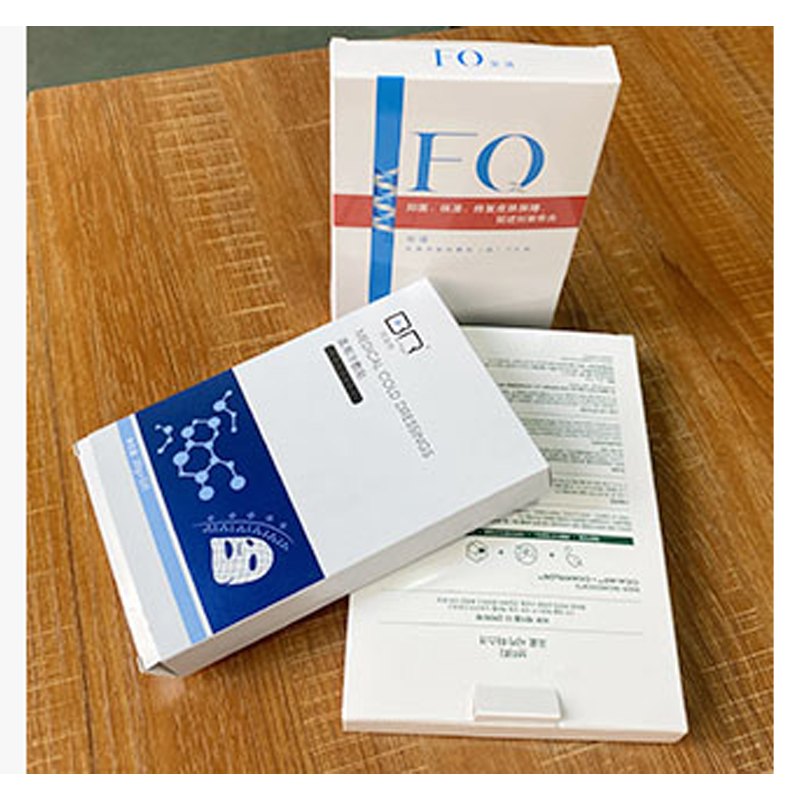

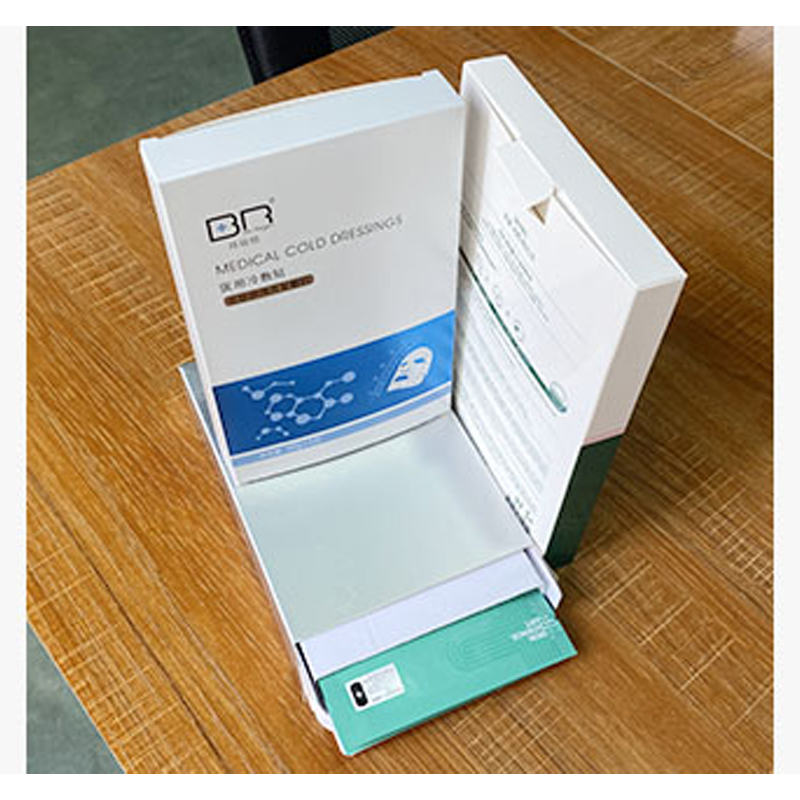

Cartoning Machine Applications

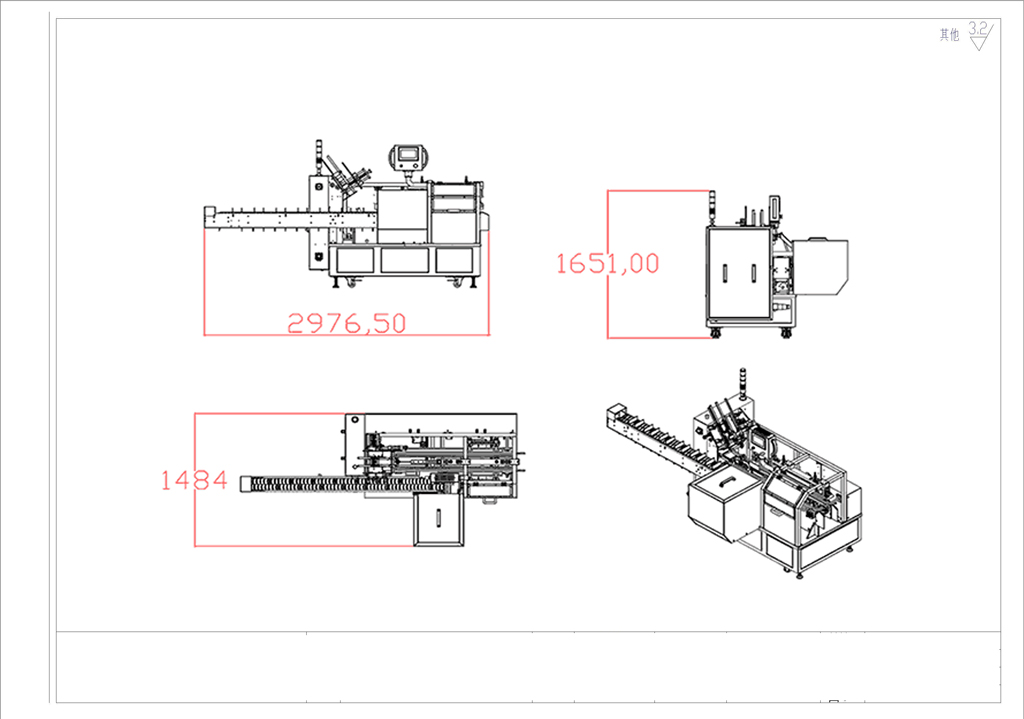

The LY200-2-560 automatic cartoning machine is a standard cartoning machine designed specifically for short cartons (such as facial masks; minimum height 15mm). It accommodates cartons ranging in size from L: 130-300 mm, W: 40-110 mm, and H: 25-70 mm. It is primarily used for automatically cartoning stationery, food, medical supplies, daily necessities, toys, auto parts, health supplements, hardware, and daily necessities.

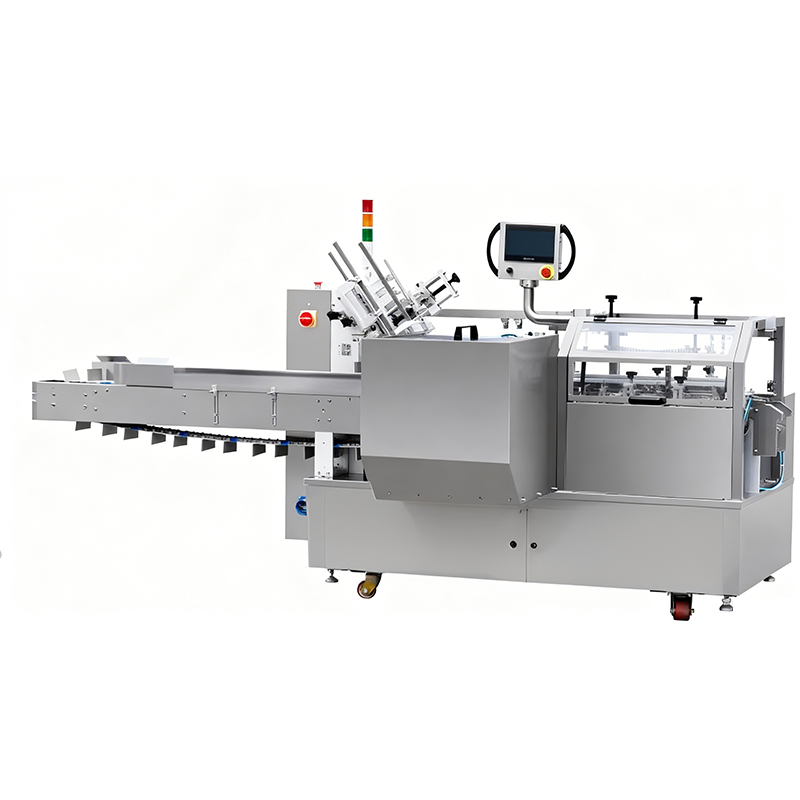

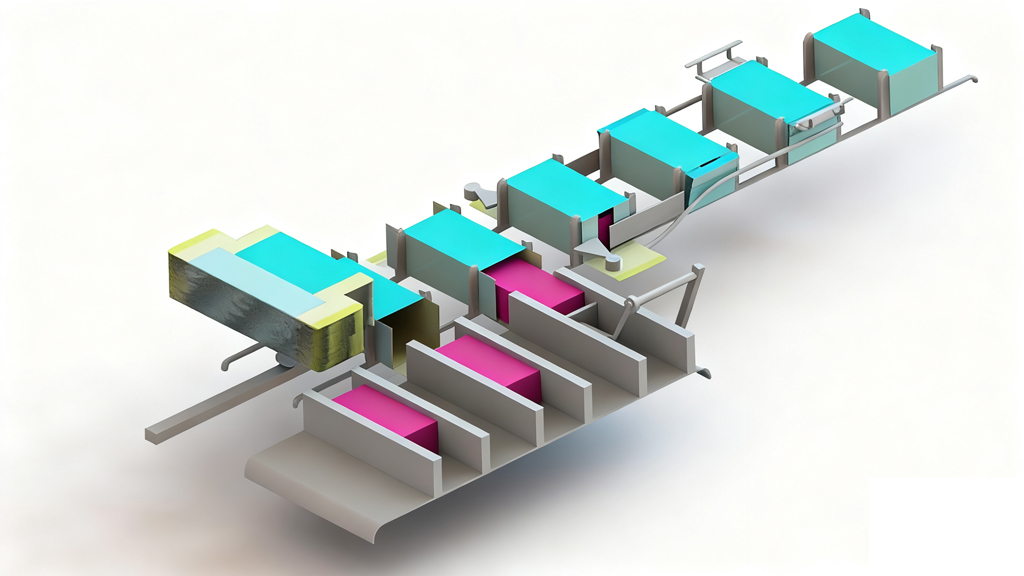

Cartoning Machine Introduction

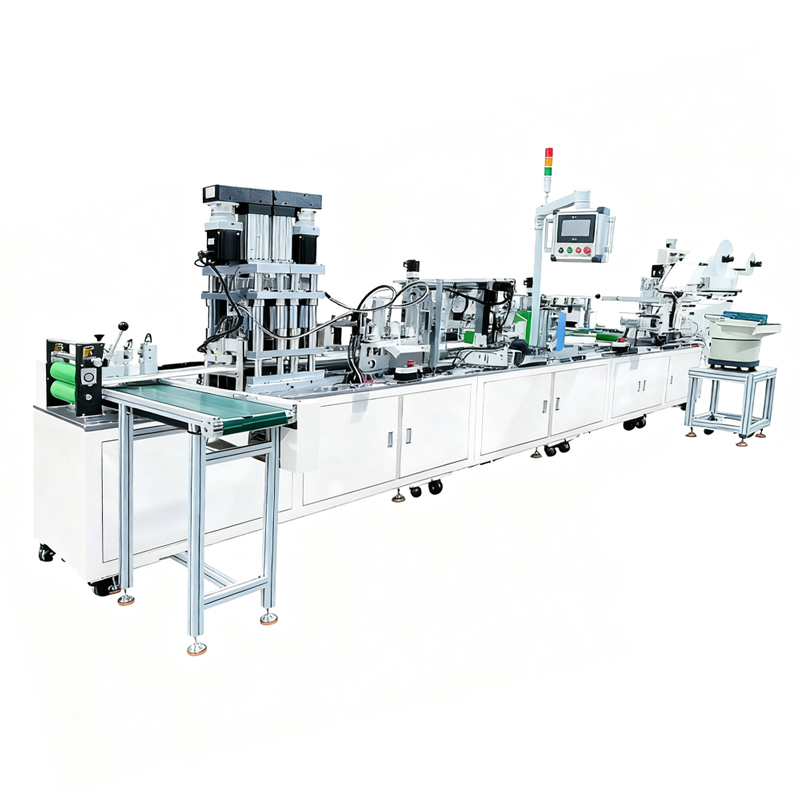

The LY200-2-560 automatic cartoning machine is compact and features a standard design that integrates automatic carton opening, packing, folding, and sealing. It can also be equipped with automatic feeding and lowering functions. Product-contact parts are constructed of SUS304 stainless steel.

The dial allows for quick adjustment of various carton sizes within the L: 130-300 mm, W: 40-110 mm, and H: 25-70 mm.

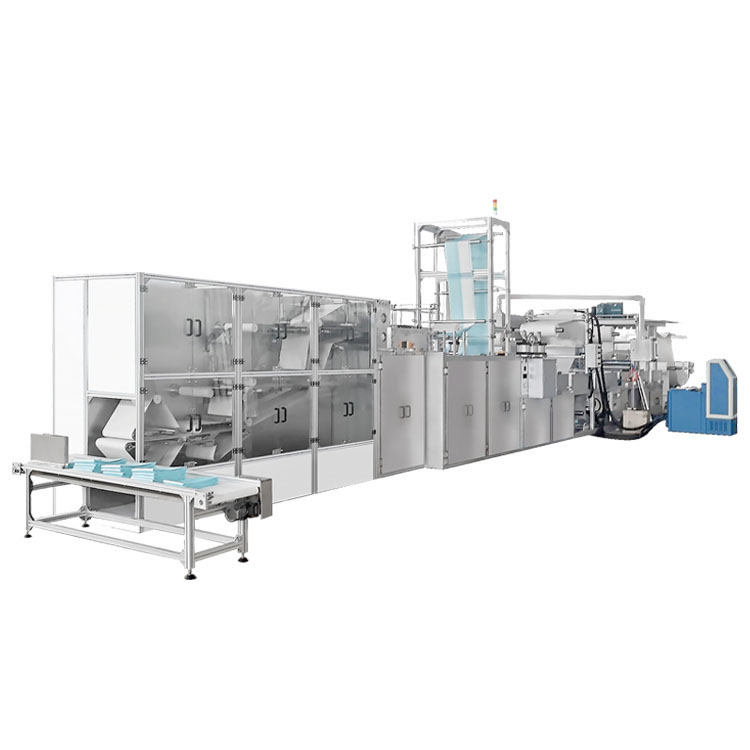

This machine can be used standalone or connected to other equipment (such as a material sorter, three-dimensional packaging machine, vertical/pillow packaging machine, labeler, inkjet printer, etc.) for coordinated operation. A hot melt glue dispenser, hot melt glue spraying, or mechanical glue brushing can be optionally configured as required.

The LY200-2-560 automatic cartoning machine features:

It can automatically add materials before and after the cartoning machine, automatically feed and unload materials, automatically load instructions, print serial numbers, and reject waste. A hot melt glue dispenser, hot melt glue spraying, or mechanical glue brushing can be configured as required.

The cartoning machine's product-contact parts are constructed of SUS304 stainless steel. The compact and rational design is simple to operate and maintain.

Highly automated: The cartoning machine utilizes a PLC programmable control system, and the human-machine interface displays parameters such as cartoning speed, quantity, automatic carton shortage alarm, carton opening failure, and fault cause. The cartoning machine's transmission and friction components are strictly manufactured in accordance with standards, resulting in less wear and tear in the later stages and reducing the need for parts replacement.