Product Introduction

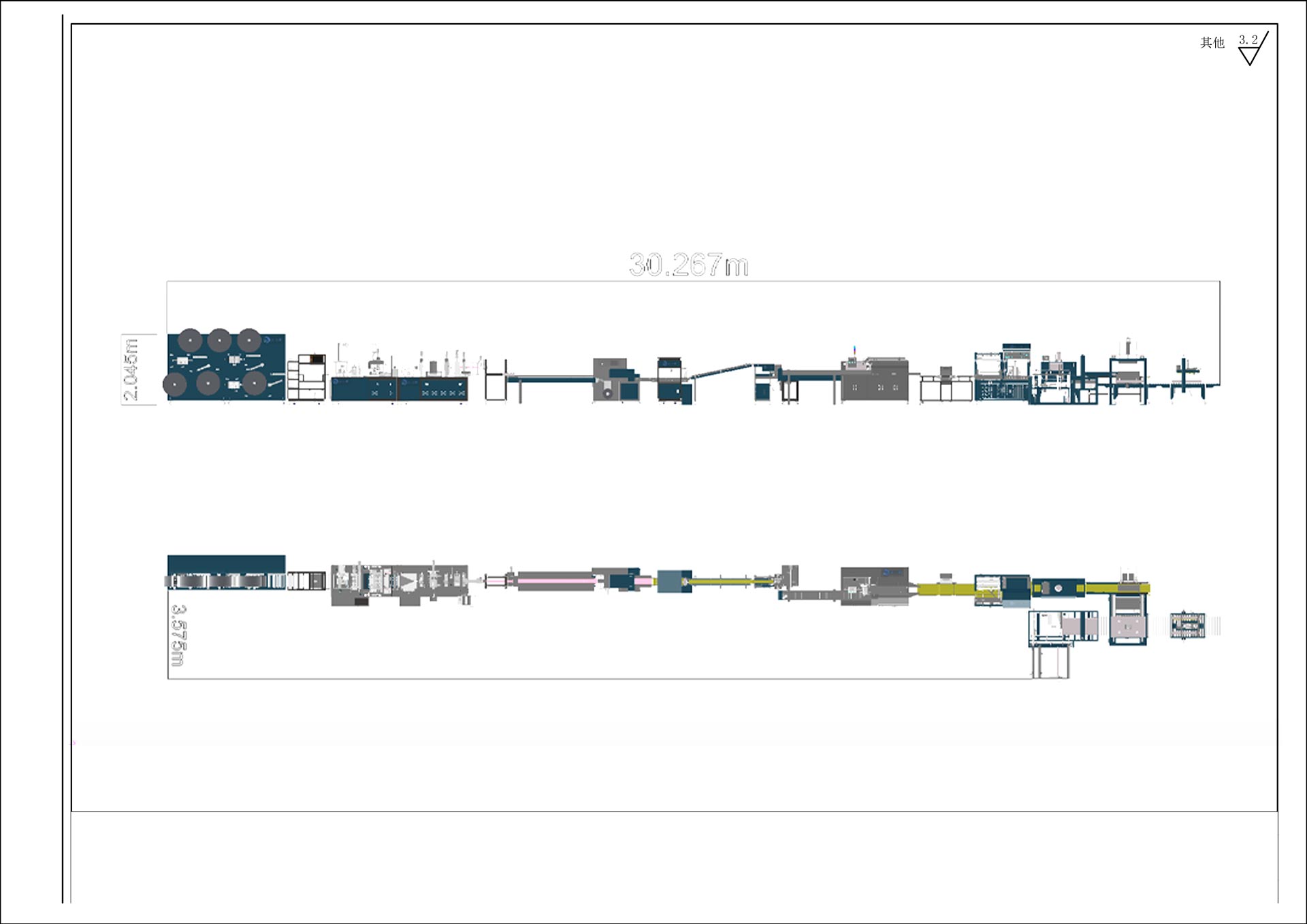

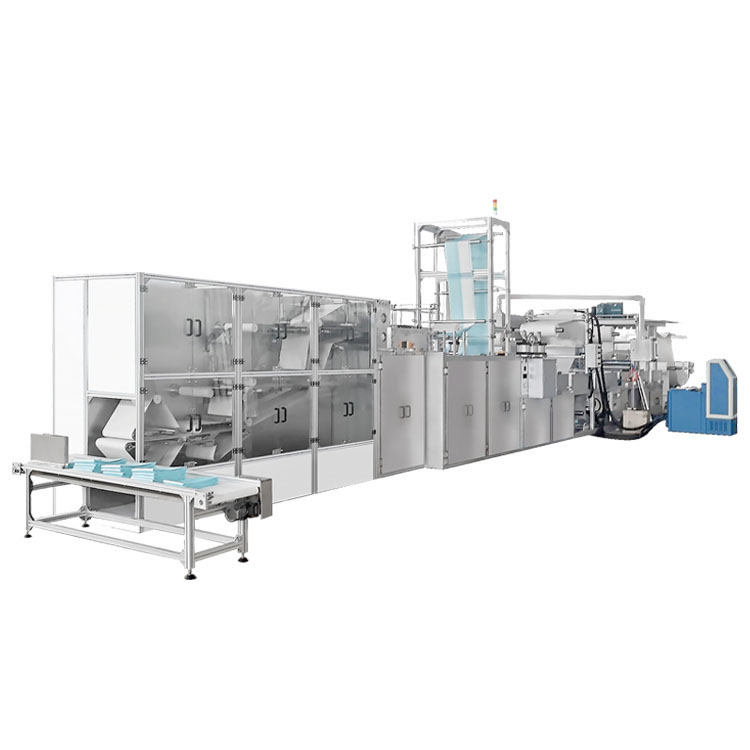

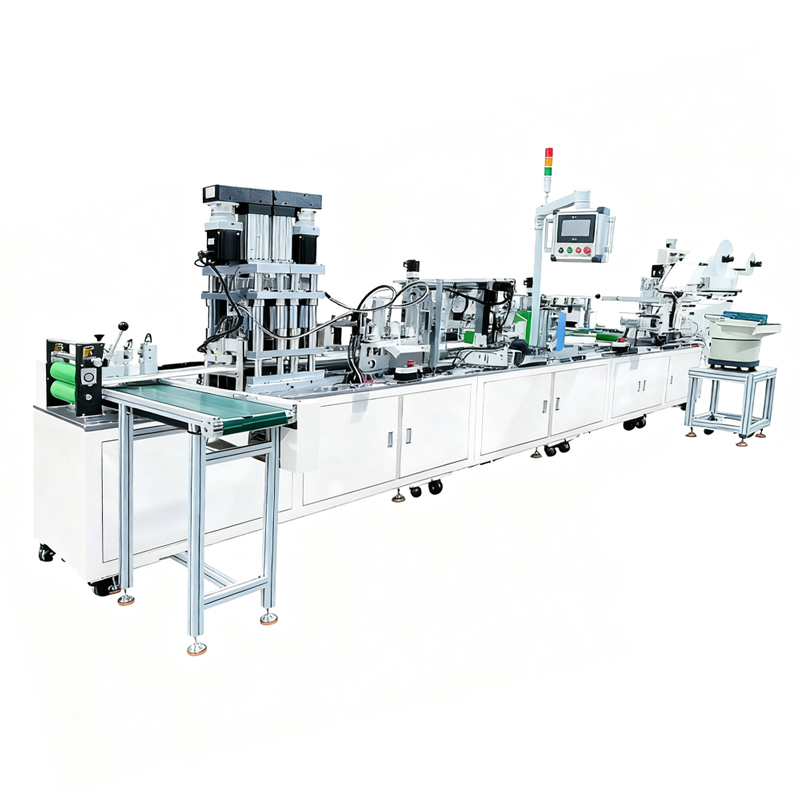

The fully automatic folding mask production and packaging line features an automatic material receiving and unloading rack. When the material runs out, new material is automatically added without stopping the machine to change materials, thereby increasing production capacity. The CCD visual inspection system detects material contamination, elastic band welding, nose bridge strips, and packaging. After production, the masks are placed in pillow packaging and plastic-sealed individually. 20 masks (a customizable quantity) are then automatically boxed by the cartoning machine. After entering the weighing and detection mechanism, they are plastic-sealed to prevent moisture, and then boxed and sealed. The entire production line can be operated unattended, and multiple mask machines can be connected to the packaging and cartoning machines, realizing an unmanned production workshop, increasing production capacity, and saving labor.