How to reduce the failure rate of automatic mask machines?

Source:http://www.loymachine.comDate:2025-09-25

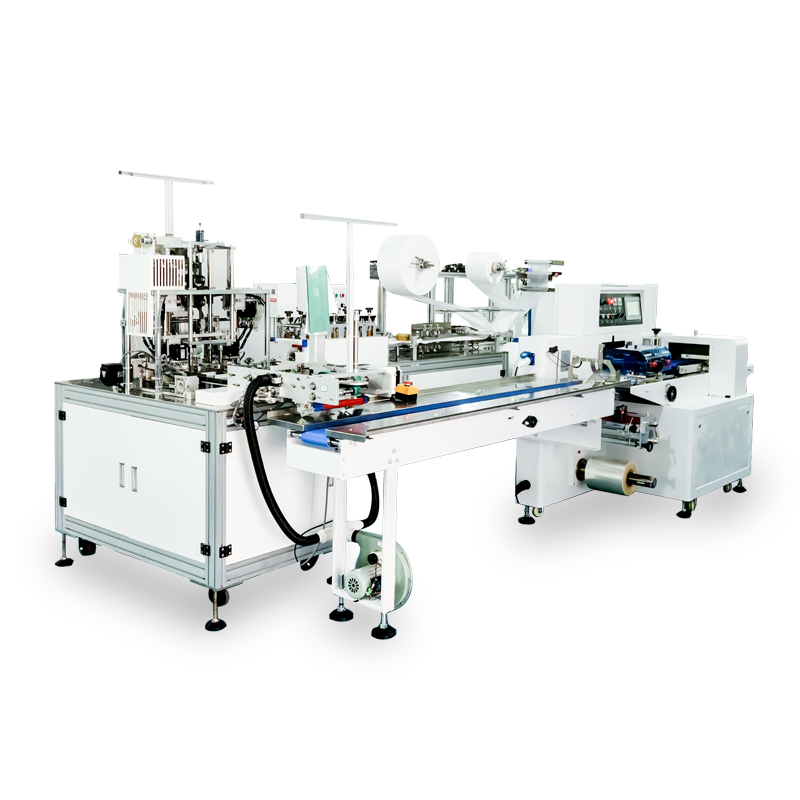

A fully automatic mask machine is an advanced mechanical operating system with a high degree of automation. From material loading to finished product delivery, the entire production process is completely automated. The integration of automation and mechanization is crucial in modern industry. This fully automatic mask machine can be operated entirely by one person, significantly increasing production capacity. How can we minimize the failure rate of such highly efficient equipment?

If a fully automatic mask machine malfunctions, the first step is to call in a qualified operator for repairs. This not only protects the machine and extends its lifespan, but also prevents damage to its components. Therefore, strengthening the maintenance and upkeep of the fully automatic mask machine can reduce many problems.

Secondly, when operating the fully automatic mask machine, production personnel should shut it down and power it off during off-duty hours. The machine should also be thoroughly inspected and cleaned. Debris and debris can be removed with alcohol and detergent. Other parts of the machine should also be checked for errors and wear. The machine's wiring, components, and electrical boxes should all be inspected and regularly maintained.

Although the fully automatic mask machine has a high mask production output and is easy to operate, it also requires daily maintenance, especially the details of the fully automatic mask machine body. The less attention is paid, the easier it is to make mistakes, so inspectors should pay more attention to it.

Recommended News

-

Equipment required for disposable mask production line

Disposable masks are made of non-woven and meltblown fabrics and are suitable for a variety of applications, including electronics manufacturing, cleanrooms, catering services, food processing, motorcycle riding, spray painting, stamping, hardware, electroplating, chemicals, steel, welding, health centers, handicrafts, beauty salons, pharmaceuticals, factories, environmental cleaning, and public spaces. So, what machines are needed to make disposable masks? Below, LOY will introduce semi-automatic and fully automatic disposable mask production equipment.I. Semi-Automatic Production Equipment1. Mask Machine(Can be equipped with a nose bridge strip)2. Ear Loop Welding Machine(Manually weld ear loops)(Automatically weld ear loops)II. Fully Automatic Production Equipment1. Fully Automatic Disp

2025-09-26 08:06:34 -

How to reduce the failure rate of mask machines?

As the mask market grows, mask machines are also a hot market. Given their relatively high prices, companies want stable operation, minimal malfunctions, and increased efficiency. So, how can mask machine failures be reduced?To minimize mask machine failures, it's important to understand the general structure and operating principles. For example, a disposable, fully automatic, one-to-one mask machine consists of a mask machine connected to a splitter. As masks are produced, they are automatically transferred to the splitter, which then transfers them to the earloop welding machine for welding, completing the mask production process.During daily mask machine operation, after each session, staff should promptly turn off the power, clean any debris from the table, wipe the machine with a

2025-09-26 08:04:11 -

What should I check when using a fully automatic mask machine?

The transmission system of a fully automatic mask machine is relatively complex. It primarily includes the ultrasonic system, air supply system, and electrical system. If any of these components malfunction, the entire machine may not start or operate properly. Before using the machine, check the following items.First, the mask machine's electrical system, primarily consisting of components such as wiring and connectors. Check for loose connectors, aging or damage to power and signal cables, dust in the electrical box, and proper heat dissipation from the exhaust fan.Second, check the machine's ultrasonic system. This system primarily consists of welding pins, an ultrasonic generator, alignment wires, and transducers. During this inspection, primarily check the ultrasonic system fo

2025-09-25 08:22:07 -

How to reduce the failure rate of automatic mask machines?

A fully automatic mask machine is an advanced mechanical operating system with a high degree of automation. From material loading to finished product delivery, the entire production process is completely automated. The integration of automation and mechanization is crucial in modern industry. This fully automatic mask machine can be operated entirely by one person, significantly increasing production capacity. How can we minimize the failure rate of such highly efficient equipment?If a fully automatic mask machine malfunctions, the first step is to call in a qualified operator for repairs. This not only protects the machine and extends its lifespan, but also prevents damage to its components. Therefore, strengthening the maintenance and upkeep of the fully automatic mask machine can reduce

2025-09-25 08:20:19